The Role of Transparency and Traceability in Sustainable Packaging

Transparency in Supply Chains

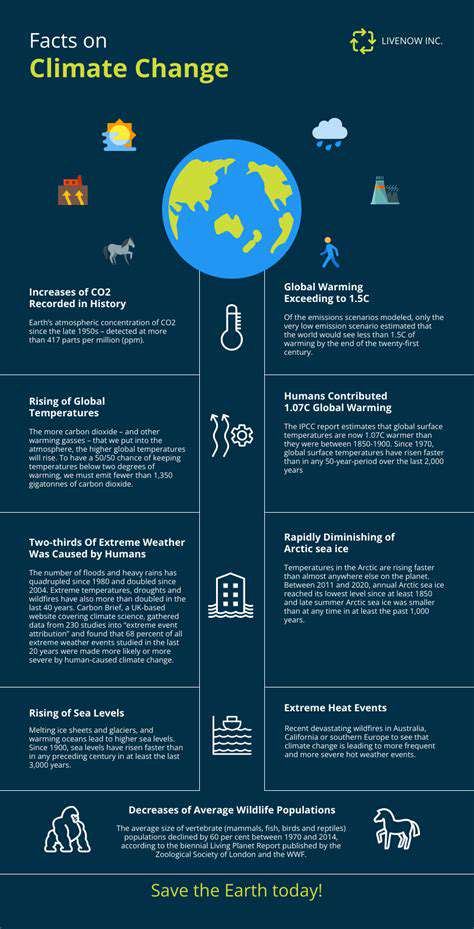

Modern businesses must prioritize supply chain transparency to foster trust with consumers and stakeholders. Knowing the origin of materials and production methods is no longer optional—it's a necessity, as buyers increasingly value accountability and ethical sourcing. Detailed insights into labor conditions, environmental footprints, and ethical production standards allow consumers to shop responsibly while helping companies uphold sustainable practices.

Forward-thinking organizations are adopting traceability tools to monitor products from raw materials to end users. These systems enhance risk mitigation, enabling rapid identification and resolution of supply chain disruptions. Transparency also streamlines operations, reducing inefficiencies and waste across the entire production cycle.

Traceability for Improved Quality Control

Robust traceability frameworks are indispensable for ensuring product consistency. By documenting every manufacturing step, producers can swiftly isolate flaws before they affect customers. This granular oversight supports proactive quality assurance, minimizing recalls while maximizing consumer confidence.

Comprehensive production logs also simplify troubleshooting. Pinpointing the source of quality lapses becomes faster, allowing for precise corrective measures that strengthen both products and brand reputation.

Benefits of Enhanced Transparency and Traceability

Investing in transparent operations yields measurable advantages. Streamlined processes and cost reductions emerge as companies use detailed data to eliminate supply chain redundancies. Fewer product recalls—and their associated expenses—further boost profitability.

Trust becomes a competitive differentiator. Today's consumers actively research the ecological and social impact of purchases. Brands that openly share their supply chain ethics align with these values, cultivating loyalty that converts to long-term revenue growth.

Consumer Demand for Transparency

The appetite for supply chain visibility is accelerating. Shoppers now recognize how globalized production affects sustainability and human welfare. This awakening forces businesses to operate with unprecedented openness or risk losing market share to more transparent competitors.

Questions about fair labor, responsible sourcing, and carbon footprints dominate purchasing decisions. This shift compels industries to redesign supply networks with verifiable sustainability at every stage.

The Future of Sustainable Prepared Food Packaging

Innovative Materials for Eco-Friendly Packaging

Food producers are aggressively pursuing greener packaging alternatives. Plant-derived bioplastics—made from corn or sugarcane—show particular promise in replacing petroleum-based options. These renewable solutions could dramatically shrink the industry's fossil fuel dependence while curbing plastic pollution.

Compostable materials present another breakthrough, though infrastructure limitations persist. Not all compostable packaging degrades equally; municipalities need specialized facilities to process these materials effectively. Solving this logistical puzzle is key to mainstream adoption.

Designing for Reduced Waste

Smarter packaging architecture directly tackles waste reduction. Engineers are rethinking container geometries, material densities, and even reusable systems to minimize resource use without compromising food safety. Some pioneers are testing packaging that serves dual purposes—protection during transport and easy recyclability post-use.

Effective designs must account for product-specific needs. Oxygen barriers, moisture controls, and temperature regulation often determine shelf life. Mastering these variables allows for minimalist packaging that still preserves freshness.

The Role of Recycling and Compostability

Scaling sustainable packaging requires massive infrastructure upgrades. Today's recycling facilities struggle with complex multi-material packages, while regional policy inconsistencies create confusion. Strategic investments in processing technology and consumer education are essential to close these gaps.

Standardized material guidelines would revolutionize recovery rates. Universal symbols indicating recyclability or compostability—paired with clear disposal instructions—could dramatically improve participation in circular systems.

Consumer Awareness and Education

Public understanding drives real change. Brands must clearly communicate how to properly dispose of packaging through intuitive labeling and community outreach. When consumers recognize their role in the waste cycle, participation in recycling and composting programs increases.

Honesty about sustainability challenges builds credibility. Companies that transparently share their packaging journey—including limitations and goals—earn consumer goodwill while accelerating industry-wide progress.

Technological Advancements and Innovation

Cutting-edge research continues to redefine possibilities. From algae-based polymers to digital watermarking for recycling robots, emerging technologies promise smarter, greener solutions. Some prototypes even integrate freshness sensors that reduce food waste by dynamically indicating quality.

These breakthroughs demonstrate how innovation can simultaneously address environmental concerns while meeting practical business needs—the hallmark of truly sustainable packaging.